One key metric drives both sustainability and ROI

April 13, 2020

Published in Coffee & Cocoa International, March 2020

Published in Coffee & Cocoa International, March 2020

Measuring and understanding Technical Efficiency can make any effort more effective and provide an understanding of the intrinsic return on investment.

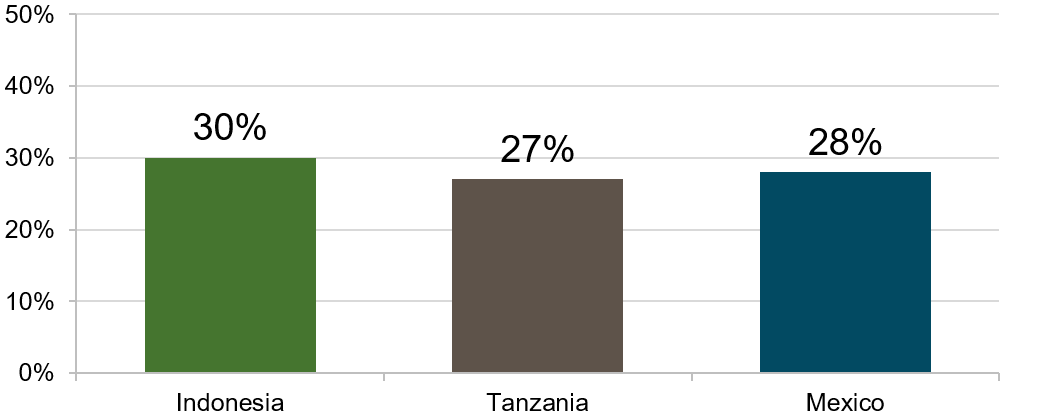

Anyone who pays for sustainability programs in farming communities - whether a company, a government, or an NGO - would benefit from paying attention to a simple metric for Technical Efficiency. It will not only make any effort substantially more effective, but also accelerate productivity goals and help leaders to understand the intrinsic return on their investment or ROI. Technical Efficiency provides valuable insights and quantifies a key facet of sustainability in a way that simple metrics like ‘productivity’ or the ‘number of farmers trained’, simply cannot. When well applied, entire farming communities can better benefit from sustainability efforts. Projected Yield Gains at Full Technical Efficiency in Three Countries

Simply put, Technical Efficiency is the measure of the farmer’s ability to convert the available factors such as land, fertilizer, labor, and agrochemicals into crops. In every farming community some farmers do that very well (high efficiency) while others fare much worse even though they operate under very similar conditions. The more efficient you are, the more you can produce given a similar set of inputs. Sounds simple, but the implications are far-reaching.

Technical Efficiency can affect sustainability or productivity efforts in three powerful ways, allowing users to:

1. Better calculate actual ROI of investments or interventions

2. Better design projects with reduced risks of failure

3. Better target resources to accelerate results while simultaneously reducing costs

1. First, for anyone investing in sustainability, Technical Efficiency captures the potential for increases in production with actual, not hypothetical, numbers. That greatly improves any estimates and the ROI calculation of any investment by basing it in actual realities. It also enhances the logical projections for a region or supplier base.

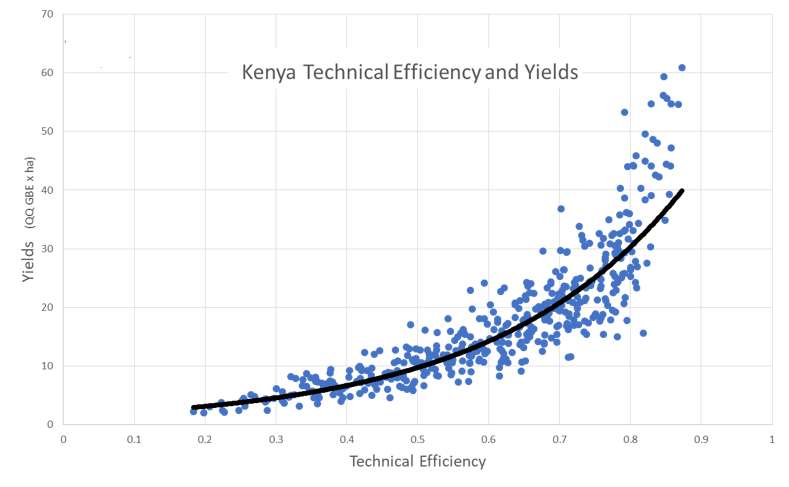

For coffee, cocoa, and other supply chains where smallholder labor dominates production, says COSA-IEP Senior Researcher Carlos De Los Rios, “Technical efficiency is at the heart of what many are trying to achieve. It’s also important to ROI. Whether for government projects or business investments, knowing the Technical Efficiency enables an understanding of precisely where to improve efficiency and of the potential economic gains of that. You can estimate that much better.” In our work over the years, we have calculated the realistic potential income and yield gains for farmers in multiple countries that would occur from improvements in their Technical Efficiency. The following graph shows the potential increase in yields of reaching the Technical Efficiency frontier. The data can show the determinants of Technical Efficiency data, an important tool to more intelligently drive efforts. 2. Second, Technical Efficiency can spot which farmers in a region have figured out or optimized their production to learn from them on site. This avoids costly experimentation or theoretical approaches and can use their success to reliably improve the pragmatic design of any productivity program in a region, supply chain, or community. They become a realistic model or benchmark of what is possible among a group of farmers. The chart below illustrates the relationship of yield to Technical Efficiency for Kenyan farmers. It is not just project design that can benefit. Enlisting the efficient farmers to train their peers is another effective approach because of the built-in trust and affinity that facilitates farmer understanding and then adoption of new practices.

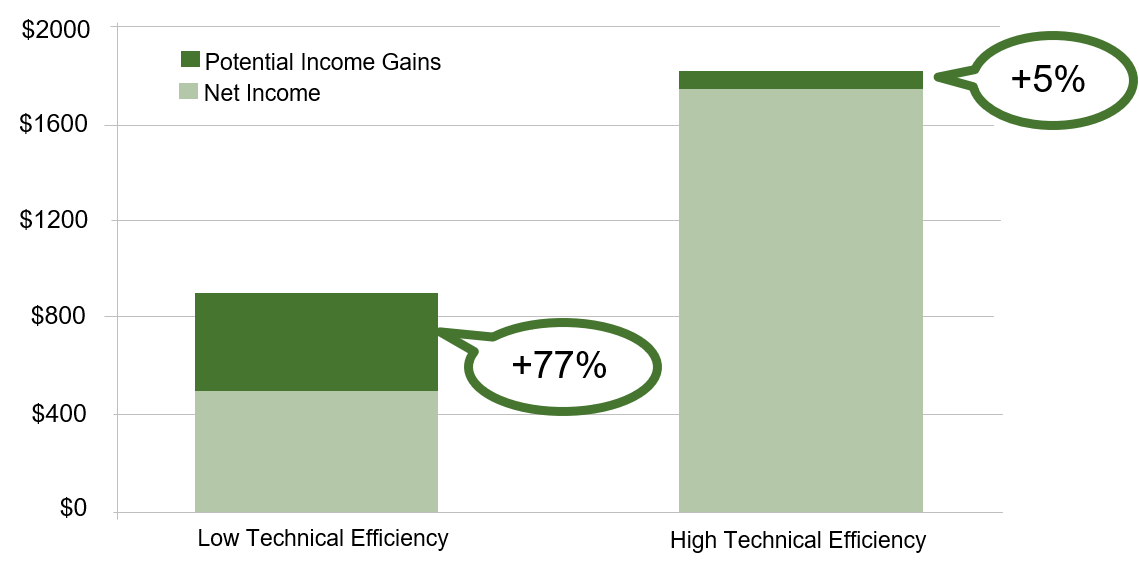

3. The third major implication of Technical Efficiency is the ability to reliably target interventions specifically to those people that need them. This will not only reduce costs but also likely improve outcomes as well. The chart below suggests that the low-efficiency group in Mexico would not only most benefit from efficiency gains but also shows the realistic potential benefits translated beyond productivity to actual income.

Using specific indicators, technical efficiency analysis lets you see who the best or most efficient farmers are. You learn how they are managing labor, how often they prune, or use fertilizers and pesticides, and thus you are able to zero in on the key levers for change. Less efficient farmers can then be better targeted with their specific areas of weakness, to at least hypothetically achieve similar results, with specific training or skill building. Resources can thus be better used and since you can target just what a farmer needs, the likelihood of their receptivity and success may be much higher.

What kind of data is needed?

To understand how well a sustainability program is achieving the intended results, most organizations monitor periodically and evaluate once or twice. The data from either monitoring or evaluation can be used for assessing Technical Efficiency. It requires expertise to apply, but it is not a costly tool.

What kind of data is needed?

To understand how well a sustainability program is achieving the intended results, most organizations monitor periodically and evaluate once or twice. The data from either monitoring or evaluation can be used for assessing Technical Efficiency. It requires expertise to apply, but it is not a costly tool.

“Analyzing technical efficiency can give you extraordinary learning,” says De Los Rios. “you can better target interventions toward producers that are often at the low end of the efficiency and productivity scale, where investment can result in the greatest change. In other words, aim your efforts to help those who are more likely to benefit and more likely to see the greatest improvements.”

Understanding technical efficiency will help companies calculate their return around farmer productivity and income, and become far more effective in any kind of intervention.

“Analyzing technical efficiency can give you extraordinary learning,” says De Los Rios. “you can better target interventions toward producers that are often at the low end of the efficiency and productivity scale, where investment can result in the greatest change. In other words, aim your efforts to help those who are more likely to benefit and more likely to see the greatest improvements.”

Understanding technical efficiency will help companies calculate their return around farmer productivity and income, and become far more effective in any kind of intervention.

[1] Technical Efficiency (TE) in farming can make a substantial livelihood difference especially for the majority of farmers who face financial and resource constraints in land, water, and other inputs. TE is also an important part of competitiveness and can serve to reduce waste and environmental contamination from inefficient resource use. It is thus a prime COSA indicator whenever data is available to calculate it. The COSA Measuring Sustainability Report, 2014.Page 46