How an innovative approach to organizing a local messaging group turned into thousands of desperately needed face masks for hospitals.

As fear mounted, Pavel Muñoz was checking the desperate feeds on his Madrid neighborhood’s messaging app in late March. The surge in new COVID 19 cases was overwhelming the healthcare system. Without adequate protection, especially plastic face shields to keep them safe, doctors and health workers were deeply concerned about getting infected. Amid the helplessness, he was drawn to a vexing problem.

He discovered that some people who owned 3D printers in his district, Alcalá de Henares, were figuring out how to make protective masks themselves for the doctors and nurses. But the scale of individual production was dwarfed by the need and, to make matters worse, there was no way for individuals to determine which clinic or hospital needed the masks. It was also tough locating people with materials and matching them to people with printers nearby. They were attempting to organize but were getting stuck trying to track things in spreadsheets. So Pavel, a Software and Technology Manager for the international NGO Committee on Sustainability Assessment, posted that he had IT skills.

A response came back quickly: could he help? He immediately realized that the sophisticated programs COSA used to track farms and supply chains in developing countries, could serve the effort. He quickly set up a user-friendly, shared data system that matched the 3D printer owners with those supplying materials. Then he applied the same system to coordinate the logistics to get the finished masks delivered in precise quantities needed at each location. And he could do all of that in real time. The high-level data dashboards Pavel created also helped to identify the best delivery routes, and where more citizen coordinators were needed so that social media could help alert interested individuals.

One problem remained: the national stay-in-place restrictions made it difficult to deliver the masks. The system he created helped to coordinate civil police to collect and distribute the masks. By then thousands of individuals across Spain were similarly organizing through messaging apps and coming together as the CoronavirusMakers, identifying the best approaches to making the protective masks.

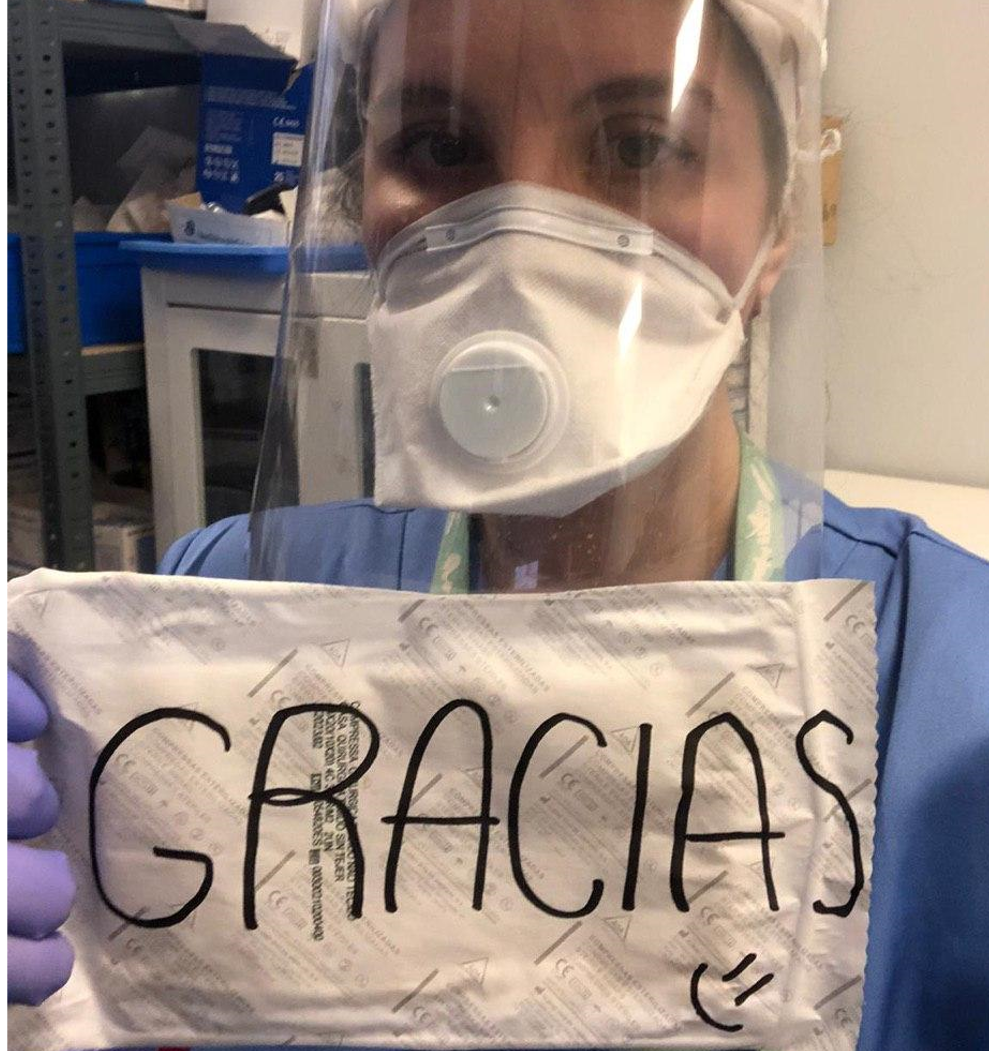

Other groups have since reached out to Pavel to set up similar data management and tracking systems. He’s been glad to contribute, even sometimes working through the night. “Instead of feeling sad and helpless about the pandemic, being able to solve the problems together of organizing and distributing masks, was deeply energizing. When the hospitals post photos with the new visor masks, well, it makes you want to keep going. It fills your spirit.”

Businesses have been supportive too, selling materials like the PVC at cost. Spain’s MediaMarkt, a distributor of consumer electronics, donated its entire stock – some 60 units – of 3D printers to the effort. More support is needed, since this volunteer-run effort depends on people some of whom may have lost their income since the start of the pandemic.

The idea is spreading and he’s even had inquiries from England. So far, his small neighborhood group has made more than 4,000 protective masks. The effort has blossomed into a civic movement across Spain providing an inspiring perspective of how caring individuals, working together, can make a massive difference. As of April 2nd, CoronavirusMakers throughout Spain have delivered more than 350,000 visor masks to Spanish hospitals.

“Each single node, by working together in a connected network, has created a deep camaraderie and strong bonds based on doing good as a community”, says Pavel. “We can’t have social events but this is a more profound social event. And, after things have quieted down, our group is still looking forward to simply having a BBQ together.”

Leave A Comment